Oil Water Seperators

Products > Oil Water Seperators

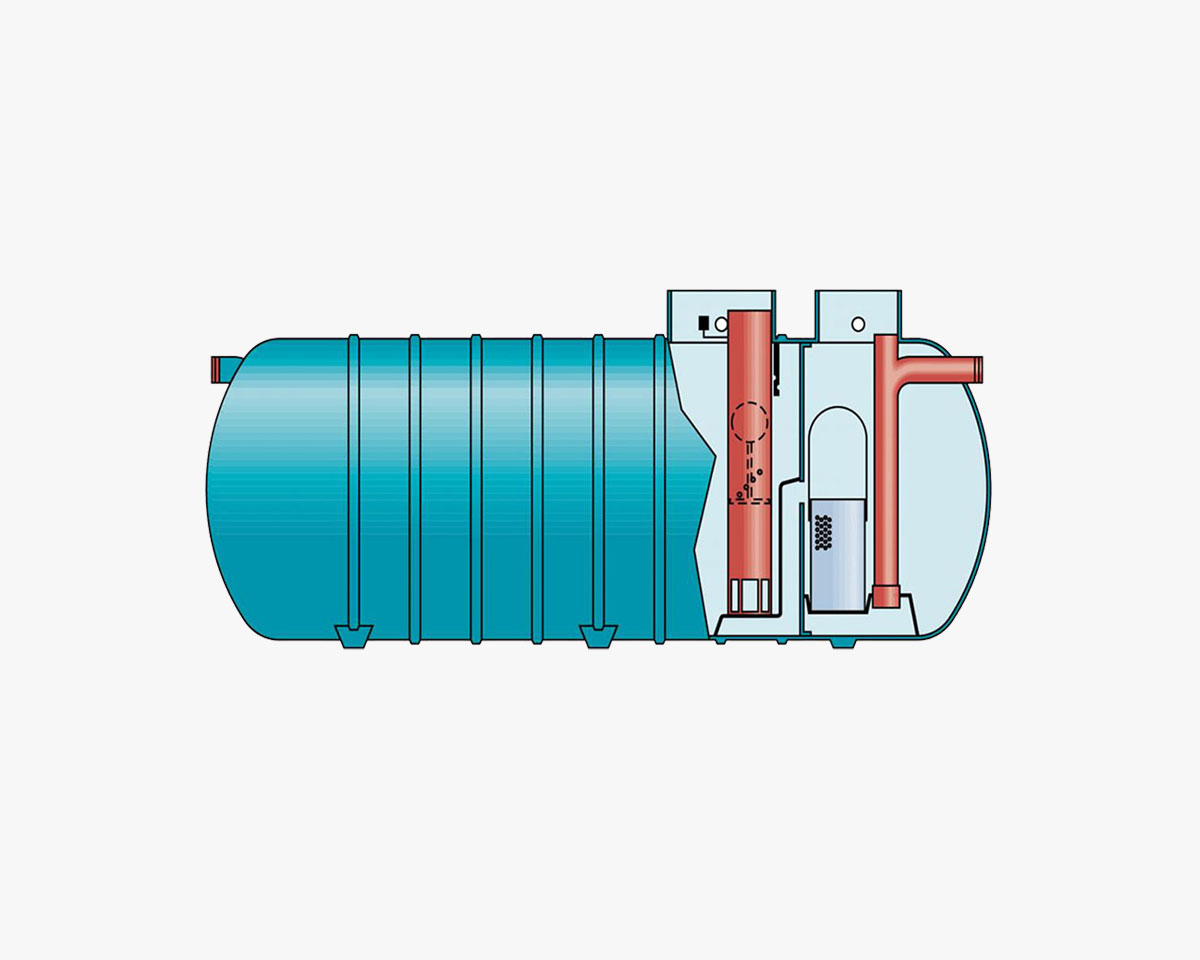

Oil Water Separators

An oil water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components. There are many different types of oil-water separator. Each has different oil separation capability and are used in different industries. Oil water separators are designed and selected after consideration of oil separation performance parameters and life cycle cost considerations. "Oil" can be taken to mean mineral, vegetable and animal oils, and the many different hydrocarbons.

Types of Oil Separators

Full Retention Separators

Full retention separators treat the full flow that can be delivered by the rainage system. This is normally equivalent to the flow generated by a rainfall intensity of 65mm/hr.

Bypass Separators

Bypass separators fully treat all flows generated by rainfall rates of up to 6.5mm/hr. This covers over 99% of all rainfall events. Flows above this rate are allowed to bypass the separator. These separators are used when it is considered an acceptable risk not to provide full treatment for high flows, for example where the risk of a large spillage and heavy rainfall occurring at the

same time is small.

Forecourt Separators

Forecourt separators are full retention separators specified to retain on site the maximum spillage likely to occur on a petrol filling station. They are required for both safety and environmental reasons and will treat spillages occurring during vehicle refueling and road tanker delivery.

Codes, Standards & Guidelines

- PPG3 Guidelines

- BSEN-858-1 & 2

- American Petroleum Institute API 421

Pollution prevention is a critical part of sustainable drainage systems and verified oil Separators are designed to protect the environment and prevent pollution of hydrocarbons (e.g. diesel, petrol or engine oil) that have entered a drainage network.